Position objects for CNC machining

An application of our diaphragm centering technique consists of using stacks of our laser-cut discs to centre and clamp mechanical pieces for their machining.

Take for example its use during the fabrication of the body of an electric motor: Once this body has been cast and left the mould, it needs to be machined to produce the holes and flanges. So there is an immediate need to manipulate the body and to position it precisely under a CNC machine.

To come to grip with such a body, the diaphragm technique is an easy and cost effective way to do just that!

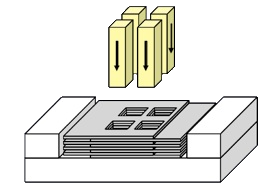

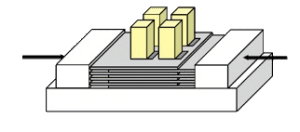

It uses laser-cut plates that fit the profile of the motor body touching this on pre-determined places. These plates are placed in opposition to form pairs that clamp the body from opposite sides. Several of these pairs of plates are stacked to obtain a tool that fits between the body and the clamping or gripping device, allowing an easy and save manipulation of the body and a solid and precise holding during the machining.

We can supply tooling, consisting of profiled discs that fit between your profiles and your clamping mechanism

Centering and clamping of an electric motor body by means of a diaphragm tool:

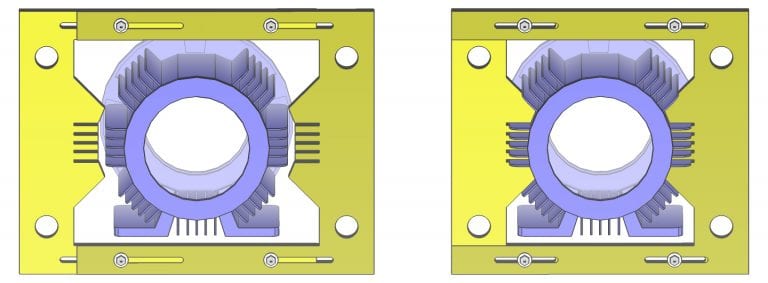

The diaphragm centering is easily extended to centre and hold more than one object and this is in particular interesting for the centering and holding of several items under a CNC machine.

Diaphragm centering applied to position multiple objects: