Centering profiled bars

The basics of our diaphragm centering technique consists of the use of stacks of laser-cut discs that have been cut to fit the profile to be centered and clamped.

The example shown here, the centering and clamping of a bar used to fabricate door-lock cylinders, uses discs that have been laser-cut to fit the profile of the bar on one side only. However the discs are stacked vice-versa to clamp on each side of the bar and a clamping mechanism (here a chuck) presses the discs against the bar. As a result one obtains a strong clamping and very precise thanks to the fact that the identical discs press from both sides cancelling possible fabrication errors of the discs.

We supply such tooling: cages with profiled discs, fitting between your profile bar and your clamping mechanism

Reasons to switch to the diaphragm centering:

- Easily centers about any shape

- Based on discs that can be produced fast and cost effective by laser cutting

- Complicated shapes create no extra cost

- The plates will even follow a twist of the bar

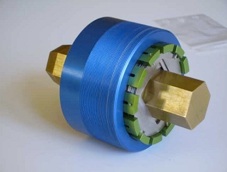

Another example is this holder clamping hexagonal bits: