Assembly of hollow profiles

Our diaphragm technique is mostly used to clamp on the outside of profiles but is also very interesting for the clamping on the inside profiles for instance for the assembly of hollow profiles.

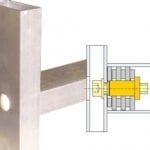

The principle is shown in the sketch. It is based on plugs, consisting of a stack of diaphragm discs, and inserted inside the profile. The discs of these plugs have been laser-cut to fit the inside of the aluminium profile and are foreseen with a slightly eccentric hole. The clamping action is obtained by stacked the identical discs in opposition such that the eccentric holes slightly overlap, and then press a cone in there that expands this plug and make it grip into the inner wall of the profile. A threaded hole in the cone allows to bolt any object to the end of the profile (here a T-connection).

Profiles can be assembled in a practically invisible way by means of such expansion plugs made from a stack of diaphragm plates.

Another example is that where diaphragm plugs are used to assemble a frame of hollow profiles.

We can supply such tooling: cages with profiled discs that grip inside your desired profile

Reasons to switch to diaphragm profile assembly:

- It is esthetical and invisible

- The plug is easily adapted to any profile section

- The profile assembly can be done on the spot, no need anymore to transport large welded assemblies